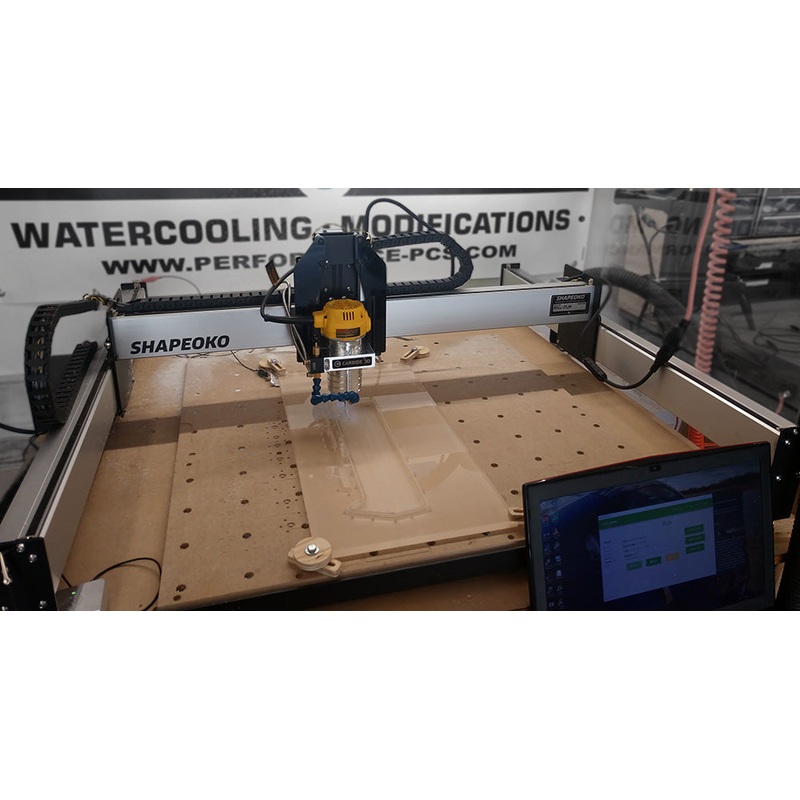

Performance-PCs proudly offers custom CNC machining! We can now accept your custom orders for mods that need to be milled. We are currently running a Shapeoko 3 XXL. You must have a fully drawn design in one of the compatible file types listed below. See below for more information on our machine and how to place a custom order.

So how do you have us make your custom mods, you might ask? Simple! Follow the guidelines specified below and come up with a 3D model (2D works for aluminum mods) for what you want us to make and send mod-proshop@ an email for a quote. Garrett will then follow up with you and plan out your mod, so you can be sure you get exactly what you want. See the compatibility list below for the file types you can use for your models.

Milling Guidelines

For Waterways

Maximum dimensions – 30? (L) x 30? (W) x .75? (H) If larger than 24? x 24?, 24? x 36? or 36? x 36? sheets will need to be purchased for your waterway and you will be charged for the entire sheet

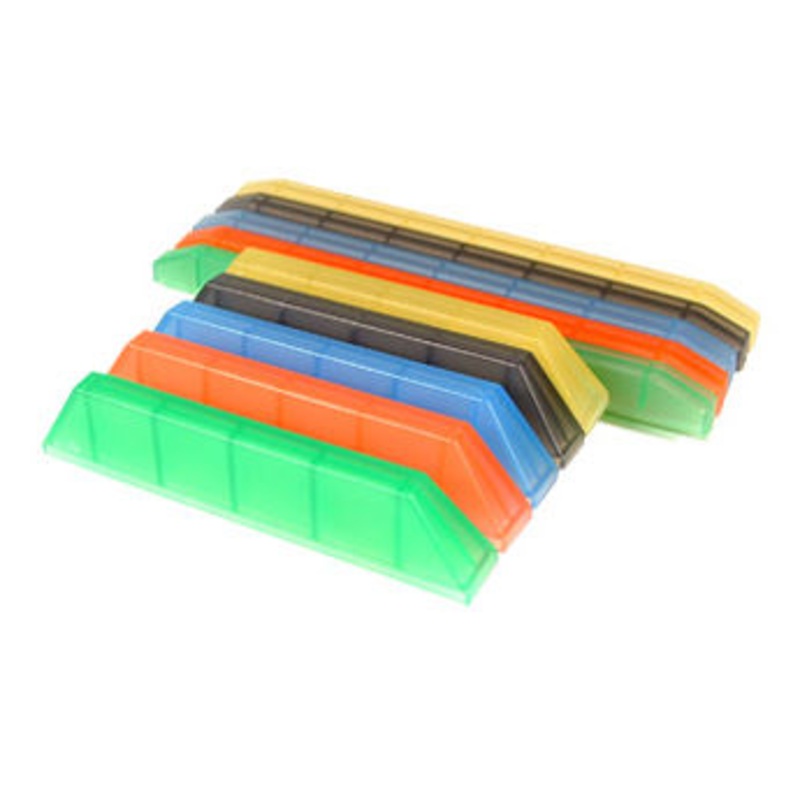

Consists of two (2) sheets of cast acrylic. 1 – 12mm (.472?) and 1 – 5.6mm (.220?) – you can Check with Garrett if you need different thicknesses.

Channels and pockets must be milled in the 12mm sheet.

2.5mm Buna 70 O-ring cord is used. Which requires the O-ring channels to be .14? wide by .06? deep. It is best to keep the channels .07? from any pockets or screw holes.

M4x16mm screws are used to secure the panels together.

Check with Garrett if you need to use a different size of O-ring.

Use .161? diameter holes for the screws in the 12mm sheet (do not thread the holes).

Use .171? diameter holes in the 5.6mm sheet.

For countersinking screws use a .371? diameter countersink at .10? deep.

Button head screws can be used instead of countersinking screws to save money on machining time if you prefer.

For direct D5 pump mounting refer to the diagram below.

Direct D5 pump mounting will cost $56 for the hardware (D5 pump top, and D5 retention ring). DOES NOT INCLUDE A D5 PUMP.

-Insert pumpmount.png with caption below ??All dimensions in inches. The 4 corner holes need to go through both sheets of acrylic. The 2 larger center holes only need to go through the top sheet of acrylic?

Try to avoid 2-sided machining jobs, i.e. the part would require more than 1 side of the stock to be milled. We can do it, however there will be an upcharge, and the accuracy of the additional sides milled can not be guaranteed.

For Aluminum

Any logos, images, etc. must be sent in .svg file format. We can not guarantee all images will work, as we are limited by the size of our endmills. The smallest we run is 1/16? in diameter, so larger images work better.

Because this will be mostly 2D work, Garrett is able to draw basic designs and patterns for you.

Panels or parts must be shipped to Garrett at the owner??s expense. – send mod-proshop@ an email for his address.

Owner will also be charged for return shipping.

Panels or parts to be milled must be flat.

File Type Compatibility List

.3dm .asm .cam360 .CATPart .CATProduct .dwg .dxf .f3d .fbx .g .iam .ige .iges .igs .ipt .neu .obj .prt .sab .sat .skp .sldasm .sldprt .smb .smt .ste .step .stl .stp .wire .x_b .x_t .123dx

PLEASE Do not order this item unless you have already discussed with us the project or custom Mod you want done. Once we have discussed it and quoted you a price then you may order this item and include the details of the project in the text box below.

To discuss this and set up your custom project or service you may e-mail us at: mod-proshop@

Reviews

There are no reviews yet.